Cutback Bitumen /Medium Curing (MC)

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures.

Medium Curing (MC)Cutback Bitumen are defined as those asphalt grades, which are prepared by using the medium volatile kerosene as the prime coat with boiling point ranges (MC-30, 70, 250, 800, 3000). The mix is done in a cold manner.

Cutback bitumen or asphalt is classified based on the curing as follows, 1. Slow, 2. Medium and 3. Rapid curing.

The degree of evaporation in the medium curing cutback asphalt is intermediate because the kerosene is intermediate volatile liquid as compared to the naphtha and diesel. The degree of liquidity depends on the proportion in which the kerosene is mixed in the asphalt cement.

The medium curing cutback bitumen is used in the flexible pavements for surface dressing, prime coating, and tack coating. Evaporation of the solvents will be at a moderate rate. This grade is used with aggregates for ensuring better workability in the mix.

The degree of liquidity developed in each case depends principally on the proportion of solvent to asphalt cement. To a minor degree, the liquidity of the cutback may be affected by the hardness of the base asphalt from which the cutback is made. The degree of fluidity results in several grades of cutback asphalt—some quite fluid at ordinary temperatures and others somewhat more viscous. The more viscous grades may require a small amount of heating to make them fluid enough for construction operations.

The medium setting grades are designed for mixing with aggregates. Because these grades do not break immediately upon contact with aggregate, mixes using them can remain workable for extended periods of time and lend themselves to cold mix stockpiles.

Applications Of Medium Curing Cutback Bitumen

The medium setting grades are designed for mixing with aggregates. Because these grades do not break immediately upon contact with aggregate, mixes using them can remain workable for extended periods of time and lend themselves to cold mix stockpiles.

Packing Of Medium Curing Cutback Bitumen

Packing of Medium Curing Cutback Bitumen is in new thick steel drums on pallet to prevent any leak inside of container also bulk in bitutainer and tanker.

Characteristics Of Medium Curing Cutback Bitumen

|

|

Medium Curing (MC) |

MC-30 |

MC-70 |

MC-250 |

MC-800 |

MC-3000 |

Test |

|||||

|

Property |

MM |

Max |

Min |

Max |

MM |

Max |

Min |

Max |

Min |

Max |

|

|

Kinematic viscosity at 60°C. mm2/s |

30 |

60 |

70 |

140 |

250 |

500 |

800 |

1600 |

3000 |

6000 |

ASTMD-2170 |

|

Flash point (Cleveland open cup). °C |

38 |

- |

38 |

66 |

- |

66 |

- |

66 |

- |

ASTM D-92 |

|

|

Distillation test: Distillate volume percent of total distillate to 360°C: |

ASTM D-402 |

||||||||||

|

to 22s °C |

35 |

- |

25 |

_ |

20 |

- |

_ |

||||

|

to 260°C |

30 |

75 |

10 |

70 |

5 |

55 |

- |

40 |

15 |

||

|

to 316°C |

75 |

95 |

65 |

93 |

60 |

90 |

45 |

85 |

15 |

75 |

|

|

Residue from distillation to 360°C, percent volume by difference |

S 0 |

- |

55 |

- |

67 |

- |

75 |

- |

80 |

- |

|

|

Tests on residue from distillation: |

|||||||||||

|

Viscosity at 60°C, Pa |

30 |

120 |

30 |

120 |

30 |

120 |

..30 |

120 |

30 |

120 |

|

|

Ductility at 25°C, cm |

100 |

- |

100 |

100 |

- |

100 |

- |

100 |

- |

ASTM D-113 |

|

|

Solubility in trichloroethylene, % |

99.0 |

- |

99.0 |

99.0 |

99.0 |

- |

99.0 |

ASTM D-4 |

|||

|

Water, % |

_ |

0.2 |

0.2 |

_ |

0.2 |

0.2 |

_ |

0.2 |

ASTM D-95 |

||

Medium Curing Cutback Bitumen Types

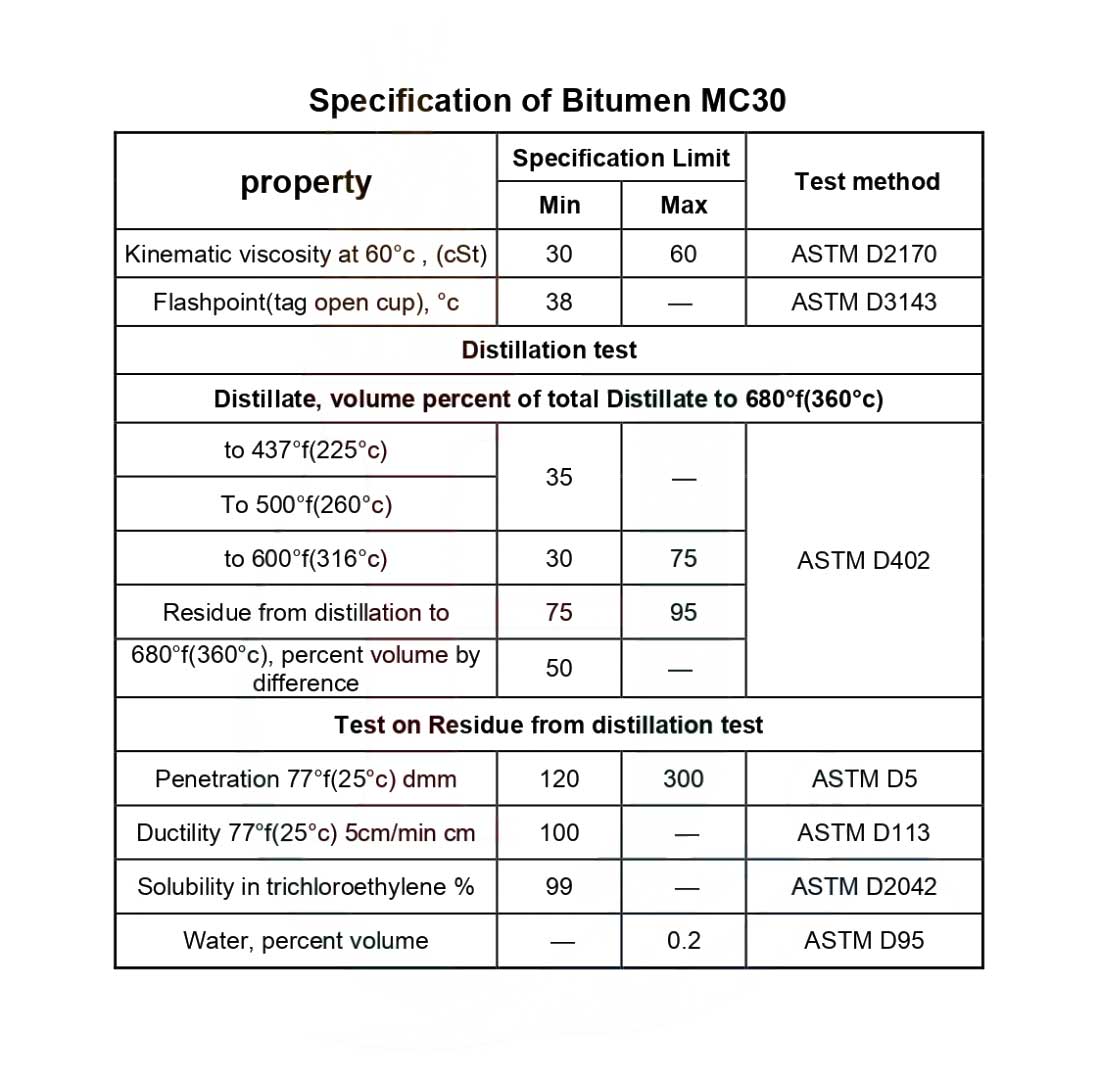

Cutback Bitumen MC-30

Cutback Bitumen MC-30 use is restricted to patching materials for use in cold weather cutback MC-30 is medium curing (MC) cut-back asphalt consisting of penetration grade asphalt cement and diluent or cutter of medium volatility. The diluent temporarily reduces the viscosity of the asphalt cement for ease of handling and application. Cutback MC-30 use in the road maintenance industry where it is used as a prime coat of the base course prior to placing of the bituminous surface course. Its purpose is to bind the granular material of the base course to the asphalt layer. Usual application is by spray using a distributor.

Cutback bitumen MC-30 is dissolved of bitumen in solvents of kerosene. In many countries, kerosene and other volatile petroleum-derived products are added as a cutter or cutback agent to bitumen to reduce (or cutback) the viscosity of the bitumen. The mixture obtained may be called cutback bitumen.

Penetration Grade bitumens are specified by the penetration and softening point test. Designation is by penetration range only. The penetration grade bitumens have a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. This unique temperature/ viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability, and application temperatures of bitumen.

Applications Of Cutback Bitumen MC-30

Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen MC-30 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction.

The cutback asphalt MC-30 applying to waterproofing of surfaces, plug capillary voids, coat and bond loose mineral particles. Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Packing Of Cutback Bitumen MC-30

This cutback bitumen bulk in the tanker and also in new steel and thick drum on the pallet to prevent all leak inside of the container.

Safety Of Cutback Bitumen MC-30

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.

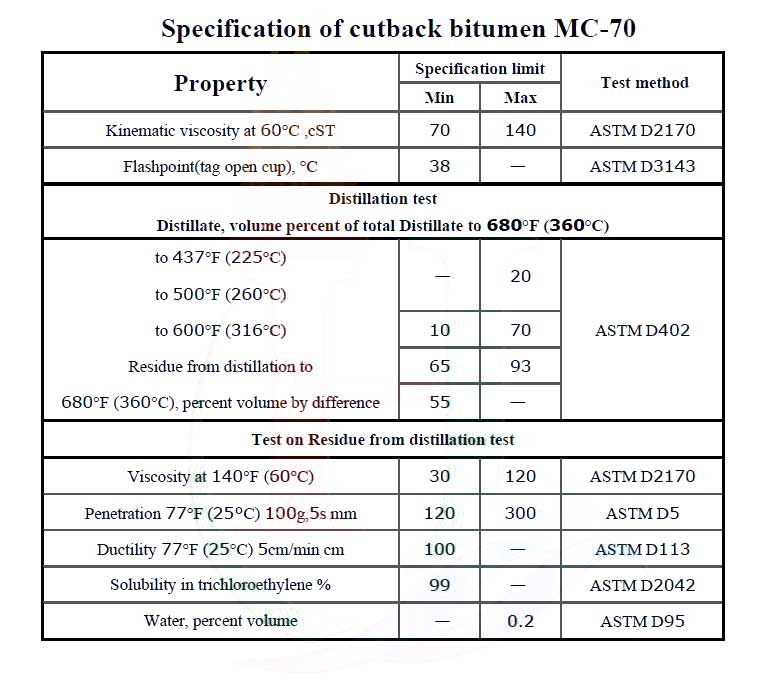

Cutback Bitumen MC-70

Cutback Bitumen MC-70 is medium curing (MC) cut-back asphalt consisting of penetration grade asphalt cement and diluent or cutter of medium volatility. The diluent temporarily reduces the viscosity of the asphalt cement for ease of handling and application. After application, the diluent evaporates, leaving asphalt cement to perform its function. Cutback MC-70 use in Roofing – As a waterproofing membrane and as an adhesive to stick chippings onto a flat, horizontal roof to minimize the effects of weathering from the sun.

Cutback bitumen MC-70 is dissolved of bitumen in solvents of kerosene. In many countries, kerosene and other volatile petroleum-derived products are added as a cutter or cutback agent to bitumen to reduce (or cutback) the viscosity of the bitumen. The mixture obtained may be called cutback bitumen. The reduction in viscosity of the bitumen aids the construction of seal coats in road pavements as the softened mixture wets the chips more easily. The cutback agent evaporates from the seal coat, the cutback agent becoming a negligible component of the seal coat a few months after application. If significant amounts of the cutback agent remain in the seal coat an unwanted long-term softening effect may result.

Our MC-70 Cutback Bitumen complies with cutback petroleum asphalts of the Medium-Curing type for use in the construction and treatment of pavements as per ASTM D2028-97 reapproved in 2004. Cutback Grade Bitumen is normally used in spraying and in some mixing applications.

Cutback Bitumen is penetration grade bitumen blended with a solvent such as kerosene, white spirit, gasoline, and naphtha, controlling the curing time. Cut back petroleum asphalts of the rapid curing type supplied by Laira Group are petroleum grade bitumen manufactured from the fractional / vacuum distillation of crude oil blended with a solvent.

Penetration Grade bitumens are specified by the penetration and softening point test. Designation is by penetration range only. The penetration grade bitumens have a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. This unique temperature/ viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability, and application temperatures of bitumen.

Application of Cutback Bitumen MC-70

Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen MC-70 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction.

The cutback asphalt MC-70 applying to waterproofing of surfaces, plug capillary voids, coat and bond loose mineral particles.

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Packing of Cutback Bitumen MC-70

Bulk as IBC Tank, Flexi Tank

Reconditioned steel drums 203 lit., Net Weight: 185 ± 5 Kg

New steel drums 203 lit., Net Weight: 185 ± 5 Kg

Guaranty and Safety of Cutback Bitumen MC-70

Laira Group guarantees the quality of cutback MC70 with the arrangement of the international inspector. By checking the quality and quantity of the bitumen on each shipment during the loading to the vessel. Also controlling the production via batch test report before shipping.

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.

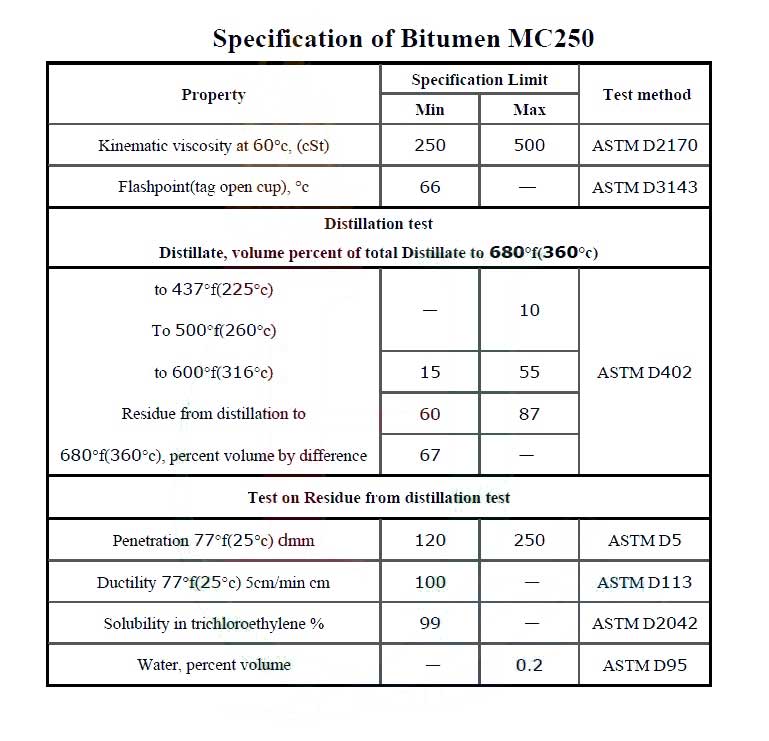

Cutback Bitumen MC-250

Cutback Bitumen MC-250 use is restricted to patching materials for use in cold weather cutback MC-250 is medium curing (MC) cut-back asphalt consisting of penetration grade asphalt cement and diluent or cutter of medium volatility. The diluent temporarily reduces the viscosity of the asphalt cement for ease of handling and application. Cutback MC-250 use in the road maintenance industry where it is used as a prime coat of the base course prior to placing of the bituminous surface course. Its purpose is to bind the granular material of the base course to the asphalt layer. Usual application is by spray using a distributor.

Cutback bitumen MC-250 is dissolved of bitumen in solvents of kerosene. In many countries, kerosene and other volatile petroleum-derived products are added as a cutter or cutback agent to bitumen to reduce (or cutback) the viscosity of the bitumen. The mixture obtained may be called cutback bitumen.

Our MC-250 Cutback Bitumen complies with cutback petroleum asphalts of the Medium-Curing type for use in the construction and treatment of pavements as per ASTM D2028-97 reapproved in 2004. Cutback Grade Bitumen is normally used in spraying and in some mixing applications.

Cutback Bitumen is penetration grade bitumen blended with a solvent such as kerosene, white spirit, gasoline, and naphtha, controlling the curing time. Cut back petroleum asphalts of the rapid curing type supplied by LAIRA GROUP are petroleum grade bitumen manufactured from the fractional / vacuum distillation of crude oil blended with a solvent.

Penetration Grade bitumens are specified by the penetration and softening point test. Designation is by penetration range only. The penetration grade bitumens have a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. This unique temperature/ viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability, and application temperatures of bitumen.

Application of Cutback bitumen MC-250

Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen MC-250 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction.

The cutback asphalt MC-250 applying to waterproofing of surfaces, plug capillary voids, coat and bond loose mineral particles.

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Packing of Cutback bitumen MC-250

Bulk as IBC Tank, Flexi Tank

Reconditioned steel drums 203 lit., Net Weight: 185 ± 5 Kg

New steel drums 203 lit., Net Weight: 185 ± 5 Kg

Guaranty and Safety of Cutback bitumen MC-250

LAIRA GROUP guarantees the quality of cutback MC250 with the arrangement of the international inspector. By checking the quality and quantity of the bitumen on each shipment during the loading to the vessel. Also controlling the production via batch test report before shipping.

Refer to Safety Data sheets before use.

Transport, use and store at the lowest temperature possible.

Eliminate all potential ignition sources during application.

Avoid breathing vapors. Avoid contact with skin.

Always wear appropriate PPE including heat protection when used hot.

DO NOT allow product or washings to enter stormwater or sewer systems.

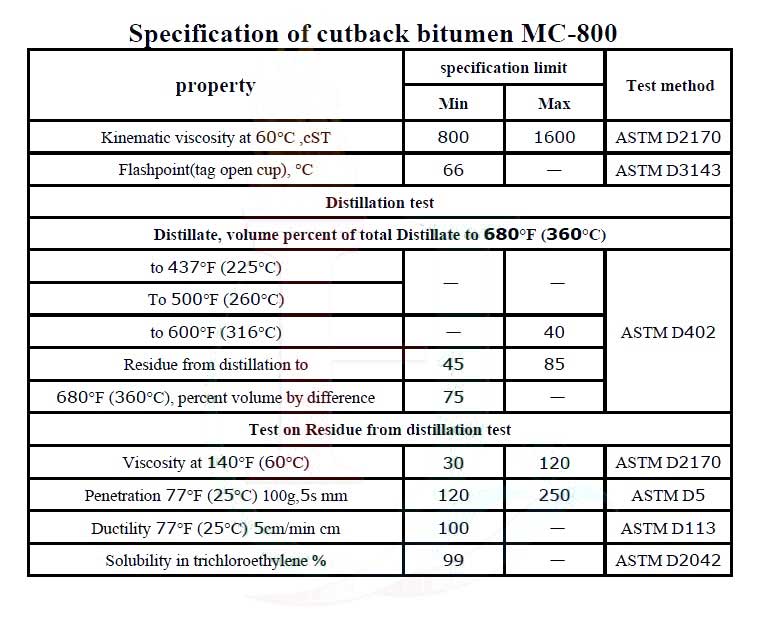

Cutback Bitumen MC-800

Cutback Bitumen MC-800 use is restricted to patching materials for use in cold weather cutback MC-800 is medium curing (MC) cut-back asphalt consisting of penetration grade asphalt cement and diluent or cutter of medium volatility. The diluent temporarily reduces the viscosity of the asphalt cement for ease of handling and application. Cutback MC-800 use in the road maintenance industry where it is used as a prime coat of the base course prior to placing of the bituminous surface course. Its purpose is to bind the granular material of the base course to the asphalt layer. Usual application is by spray using a distributor.

Our MC-800 Cutback Bitumen complies with cutback petroleum asphalts of the Medium-Curing type for use in the construction and treatment of pavements as per ASTM D2028-97 reapproved in 2004. Cutback Grade Bitumen is normally used in spraying and in some mixing applications.

Cutback Bitumen is penetration grade bitumen blended with a solvent such as kerosene, white spirit, gasoline, and naphtha, controlling the curing time. Cut back petroleum asphalts of the rapid curing type supplied by LAIRA GROUP are petroleum grade bitumen manufactured from the fractional / vacuum distillation of crude oil blended with a solvent.

Penetration Grade bitumens are specified by the penetration and softening point test. Designation is by penetration range only. The penetration grade bitumens have a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures.

This unique temperature/ viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability, and application temperatures of bitumen.

Applications Of Cutback Bitumen MC-800

Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen MC-800 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction.

The cutback asphalt MC-800 applying to waterproofing of surfaces, plug capillary voids, coat and bond loose mineral particles.

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Packing Of Cutback Bitumen MC-800

This cutback bitumen bulk in the tanker and also in new steel and thick drum on the pallet to prevent all leak inside of the container.

Safety Of Cutback Bitumen MC-800

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.

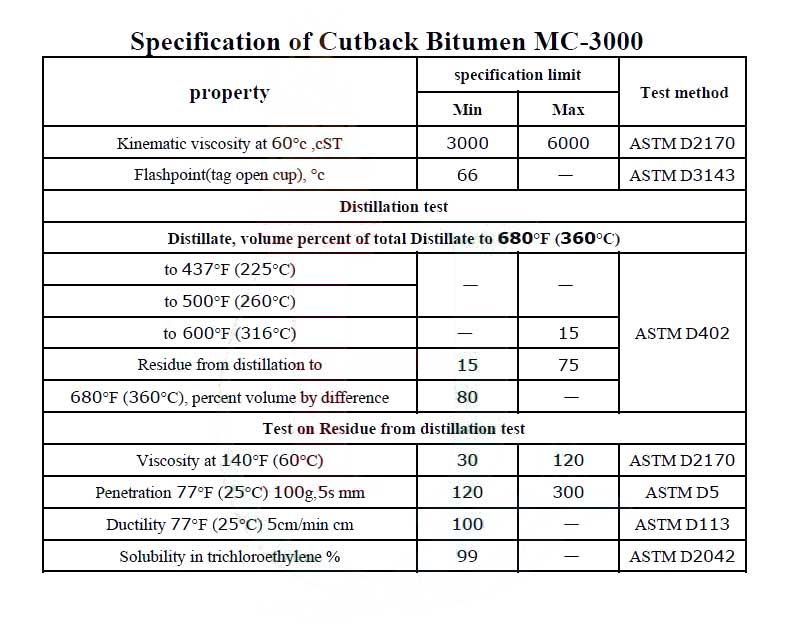

Cutback Bitumen MC-3000

Cutback Bitumen MC-3000 is dissolved of bitumen in solvents of kerosene. In many countries, kerosene and other volatile petroleum-derived products are added as a cutter or cutback agent to bitumen to reduce (or cutback) the viscosity of the bitumen. The mixture obtained may be called cutback bitumen.

The reduction in viscosity of the bitumen aids the construction of seal coats in road pavements as the softened mixture wets the chips more easily. The cutback agent evaporates from the seal coat, the cutback agent becoming a negligible component of the seal coat a few months after application. If significant amounts of the cutback agent remain in the seal coat an unwanted long-term softening effect may result.

Our Cutback Bitumen MC-3000 complies with cutback petroleum asphalts of the Medium-Curing type for use in the construction and treatment of pavements as per ASTM D2028-97 reapproved in 2004. Cutback Grade Bitumen is normally used in spraying and in some mixing applications.

Cutback Bitumen is penetration grade bitumen blended with a solvent such as kerosene, white spirit, gasoline, and naphtha, controlling the curing time. Cut back petroleum asphalts of the rapid curing type supplied by LAIRA GROUP are petroleum grade bitumen manufactured from the fractional / vacuum distillation of crude oil blended with a solvent.

Penetration Grade bitumens are specified by the penetration and softening point test. The designation is by penetration range only. The penetration grade bitumens have a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures.

This unique temperature/ viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability, and application temperatures of bitumen.

Applications Of Cutback Bitumen MC-3000

Cutback asphalt is an asphalt cement that has a solvent or distillate such as gasoline, diesel fuel, kerosene, or naphtha added to make the asphalt liquid at ambient temperatures and improve its ability to coat aggregates. Two letters followed by a numerical digit designate or name a cutback asphalt.

Cutback asphalt can contain between 12 and 40 percent distillate. The high demand for the distillates to be used in energy applications and ever-increasing air quality regulations have caused a steady decline in the use of cutback asphalt.

Cutback agents are used to lowering the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen MC-3000 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction. The cutback asphalt MC3000 applying to waterproofing of surfaces, plug capillary voids, coat and bond loose mineral particles.

Packing Of Cutback Bitumen MC-3000

This cutback bitumen bulk in the tanker and also in new steel and thick drum on the pallet to prevent all leak inside of the container.

Safety Of Cutback Bitumen MC-3000

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.