Cutback Bitumen /Slow-Curing (SC)

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures.

Slow curing Cutback Bitumen and oils of low volatility generally in the heavy distillate range (SC-70, 250, 800, 3000). The degree of liquidity developed in each case depends principally on the proportion of solvent to asphalt cement. To a minor degree, the liquidity of the cutback may be affected by the hardness of the base asphalt from which the cutback is made. The degree of fluidity results in several grades of cutback bitumen - some quite fluid at ordinary temperatures and others somewhat more viscous. The more viscous grades may require a small amount of heating to make them fluid enough for construction operations.

Slow Curing often called “road oils,” are usually a residual material produced from the fractional distillation of certain crude petroleums. Traditionally any kind of aromatic, naphthenic and paraffinic oils are used. Slow Curing liquid bitumen materials can be prepared by blending bitumen with an oily petroleum fraction.

Cutback agents are used to lowering the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Slow Curing Cutback Bitumen Types

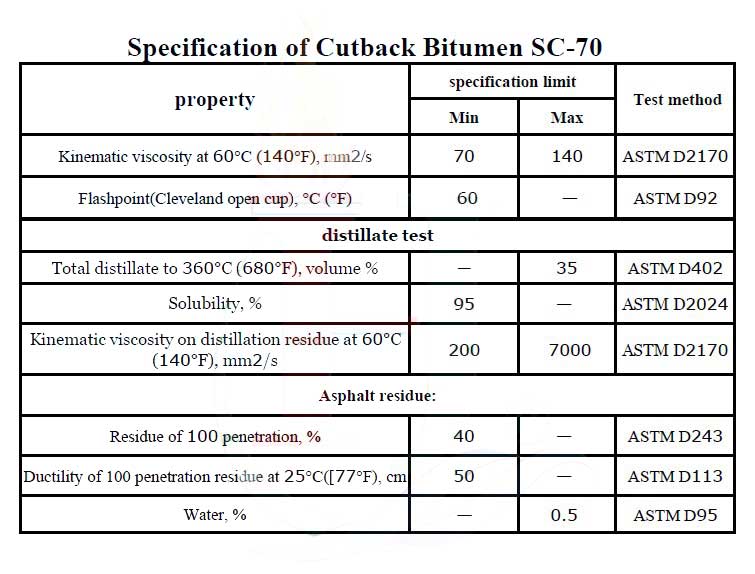

Cutback Bitumen SC-70

Cutback asphalt is an asphalt cement that has a solvent or distillate such as gasoline, diesel fuel, kerosene, or naphtha added to make the asphalt liquid at ambient temperatures and improve its ability to coat aggregates. Two letters followed by a numerical digit designate or name a cutback asphalt.

Cutback asphalt can contain between 12 and 40 percent distillate. The high demand for the distillates to be used in energy applications and ever-increasing air quality regulations have caused a steady decline in the use of cutback asphalt.

The SC liquid asphalt may be obtained by fluxing an asphalt cement with a less volatile distillate such as gas oil. The SC-70 and SC-250 grade cutback asphalts are very similar to residual refinery products that are used as heavy fuel oils such as bunker C or Number six fuel oils. These SC cutback materials, whether straight run or fluxed with a relatively non-volatile material such as gas oil, are also known as “road oils”.

Applications Of Cutback Bitumen SC-70

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Cutback agents are used to lowering the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements. The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen SC-70 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction. The cutback asphalt SC-70 applying to waterproofing of surfaces, plug capillary voids, coat and bond loose mineral particles.

Packing Of Cutback Bitumen SC-70

Packing of cutback bitumen SC-70 is in the new thick steel drum on the pallet to prevent any leak inside of container also bulk in bitutainers and tanker.

Safety Of Cutback Bitumen SC-70

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter storm-water or sewer systems.

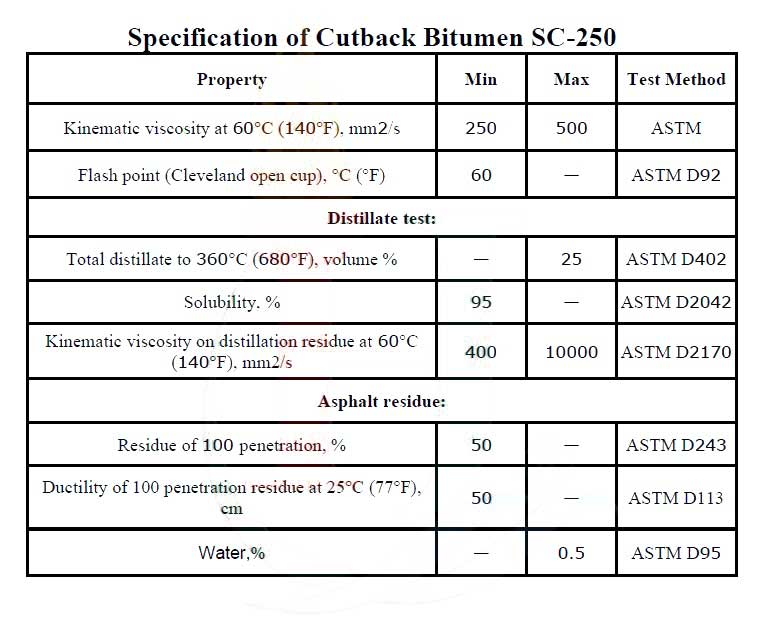

Bitumen SC-250

Cutback Bitumen SC-250 is an asphalt cement that has a solvent or distillate such as gasoline, diesel fuel, kerosene, or naphtha added to make the asphalt liquid at ambient temperatures and improve its ability to coat aggregates. Two letters followed by a numerical digit designate or name a cutback asphalt.

Cutback asphalt can contain between 12 and 40 percent distillate. The high demand for the distillates to be used in energy applications and ever-increasing air quality regulations have caused a steady decline in the use of cutback asphalt.

The SC liquid asphalt may be obtained by fluxing an asphalt cement with a less volatile distillate such as gas oil. The SC-70 and SC-250 grade cutback asphalts are very similar to residual refinery products that are used as heavy fuel oils such as bunker C or Number six fuel oils. These SC cutback materials, whether straight run or fluxed with a relatively non-volatile material such as gas oil, are also known as “road oils”.

Applications Of Cutback Bitumen SC-250

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen SC-250 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction. The cutback asphalt SC-250 applying to waterproofing of surfaces plug capillary voids, coat and bond loose mineral particles.

Packing Of Cutback Bitumen SC-250

Packing of cutback bitumen SC-250 is in the new thick steel drum on the pallet to prevent any leak inside of container also bulk in bitutainers and tanker.

Safety Of Cutback Bitumen SC-250

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.

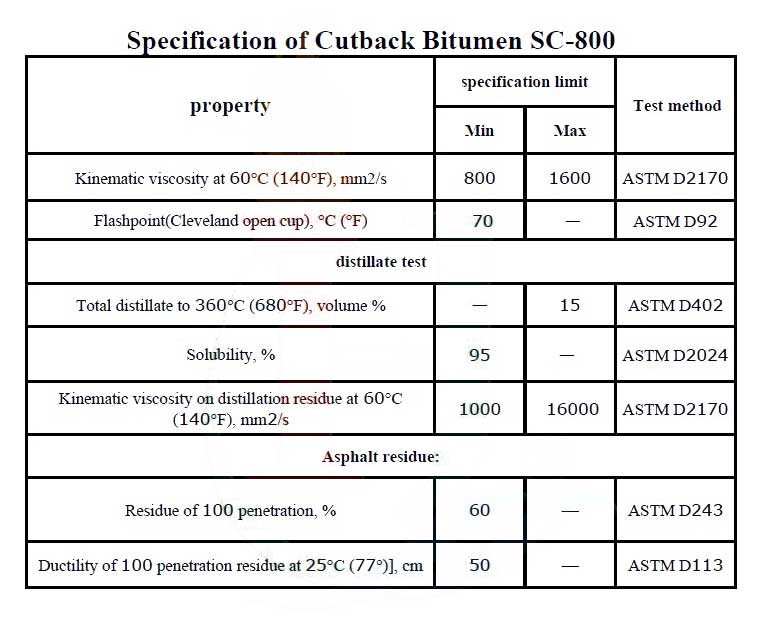

Bitumen SC-800

Cutback asphalt is an asphalt cement that has a solvent or distillate such as gasoline, diesel fuel, kerosene, or naphtha added to make the asphalt liquid at ambient temperatures and improve its ability to coat aggregates. Two letters followed by a numerical digit designate or name a cutback asphalt.

Cutback Bitumen SC-800 can contain between 12 and 40 percent distillate. The high demand for the distillates to be used in energy applications and ever-increasing air quality regulations have caused a steady decline in the use of cutback asphalt.

The SC liquid asphalt may be obtained by fluxing an asphalt cement with a less volatile distillate such as gas oil. The SC-70 and SC-250 grade cutback asphalts are very similar to residual refinery products that are used as heavy fuel oils such as bunker C or Number six fuel oils. These SC cutback materials, whether straight run or fluxed with a relatively non-volatile material such as gas oil, are also known as “road oils”.

Applications Of Cutback Bitumen SC-800

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface.

Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen SC-800 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction. The cutback bitumen SC-800 applying to waterproofing of surfaces plug capillary voids, coat and bond loose mineral particles.

Packing Of Cutback Bitumen SC-800

This cutback bitumen bulk in the tanker and also in new steel and thick drum on the pallet to prevent all leak inside of the container.

Safety Of Cutback Bitumen SC-800

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.

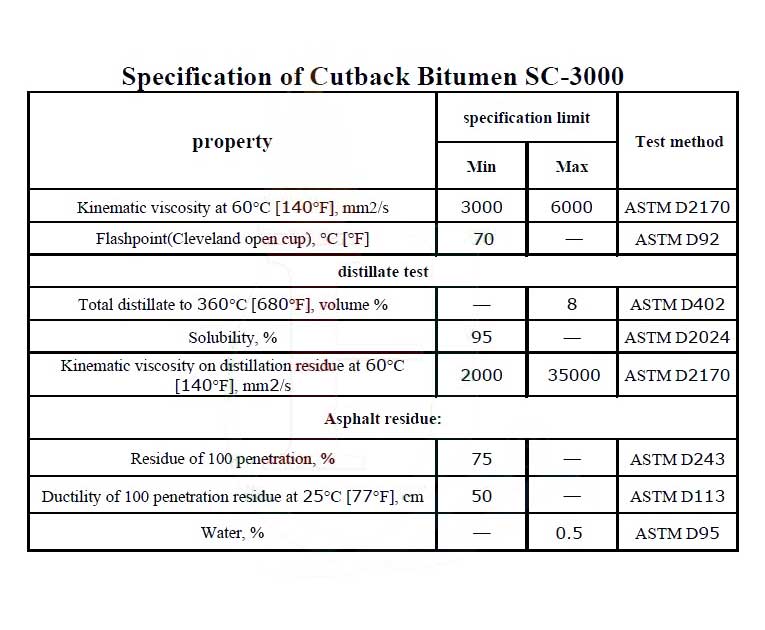

Bitumen SC-3000

Cutback asphalt is an asphalt cement that has a solvent or distillate such as gasoline, diesel fuel, kerosene, or naphtha added to make the asphalt liquid at ambient temperatures and improve its ability to coat aggregates. Two letters followed by a numerical digit designate or name a cutback asphalt.

Cutback Bitumen SC-3000 can contain between 12 and 40 percent distillate. The high demand for the distillates to be used in energy applications and ever-increasing air quality regulations have caused a steady decline in the use of cutback asphalt.

The SC liquid asphalt may be obtained by fluxing an asphalt cement with a less volatile distillate such as gas oil. The SC-70 and SC-250 grade cutback asphalts are very similar to residual refinery products that are used as heavy fuel oils such as bunker C or Number six fuel oils. These SC cutback materials, whether straight run or fluxed with a relatively non-volatile material such as gas oil, are also known as “road oils”.

Applications Of Cutback Bitumen SC-3000

Current common uses are in penetrating prime coats and in producing patching or stockpile mixtures. Cutback asphalt used in mixing with aggregate will usually contain an adhesion agent to assist in the coating of the aggregate surface. Cutback agents are used to lower the viscosity of bitumen when it is applied as a primer to the surface of a road pavement aggregate base course or substrate. Kerosene is used as a bitumen cutback agent at different concentrations according to local conditions and requirements.

The cutback bitumen is ideal for prime coat and cold applied because of easy uses and no need to thinning and heating.

Cutback bitumen SC-3000 consist of initial incorporation of asphalt into the surface of non-asphalt based course preparatory to any superimposed treatment of construction .

The cutback asphalt SC-3000 applying to waterproofing of surfaces plug capillary voids, coat and bond loose mineral particles.

Packing Of Cutback Bitumen SC-3000

Packing of cutback bitumen SC-3000 is in the new thick steel drum on the pallet to prevent any leak inside of container also bulk in bitutainers and tanker.

Safety Of Cutback Bitumen SC-3000

1.Refer to Safety Data sheets before use.

2.Transport, use and store at the lowest temperature possible.

3.Eliminate all potential ignition sources during application.

4.Avoid breathing vapors. Avoid contact with skin.

5.Always wear appropriate PPE including heat protection when used hot.

6.DO NOT allow product or washings to enter stormwater or sewer systems.